In recent years, there has been a growing emphasis on energy efficiency in the construction industry. As a result, significant advancements have been made in the production of energy-saving glass. This article explores the importance of energy efficiency in buildings, specifically focusing on innovations in the manufacturing of energy-saving glass. We will discuss the benefits of energy-saving glass, explore various manufacturing techniques, and highlight the standards and regulations set by standardization bodies to promote energy-efficient glass production.

The Importance of Energy Efficiency in Buildings

Energy efficiency plays a crucial role in reducing energy consumption, minimizing greenhouse gas emissions, and lowering utility costs. Buildings are responsible for a significant portion of global energy consumption, and inefficient windows and glazing systems contribute to heat loss, excessive solar heat gain, and increased reliance on heating, ventilation, and air conditioning (HVAC) systems. Improving the energy performance of windows and glass is essential in achieving sustainable and environmentally friendly buildings.

Benefits of Energy-Saving Glass

Energy-saving glass, also known as low-emissivity (low-E) glass, offers several benefits in terms of energy efficiency. It is designed to reduce the amount of heat transfer through windows while allowing natural light to enter the building. By controlling the amount of solar radiation and heat that enters or escapes a building, energy-saving glass helps maintain comfortable indoor temperatures year-round. This, in turn, reduces the reliance on HVAC systems, resulting in significant energy savings and decreased carbon emissions. Which windows to choose for historical buildings? Read more here.

Innovations in Energy-Saving Glass Manufacturing

Manufacturers have developed various innovative techniques to enhance the energy efficiency of glass. These advancements focus on improving the thermal insulation properties, solar control capabilities, and overall performance of the glass. Some notable innovations include:

- Low-E Coatings: Low-E coatings are microscopically thin layers of metal or metal oxide applied to the surface of the glass. They reflect thermal radiation while allowing visible light to pass through, reducing heat transfer and improving insulation.

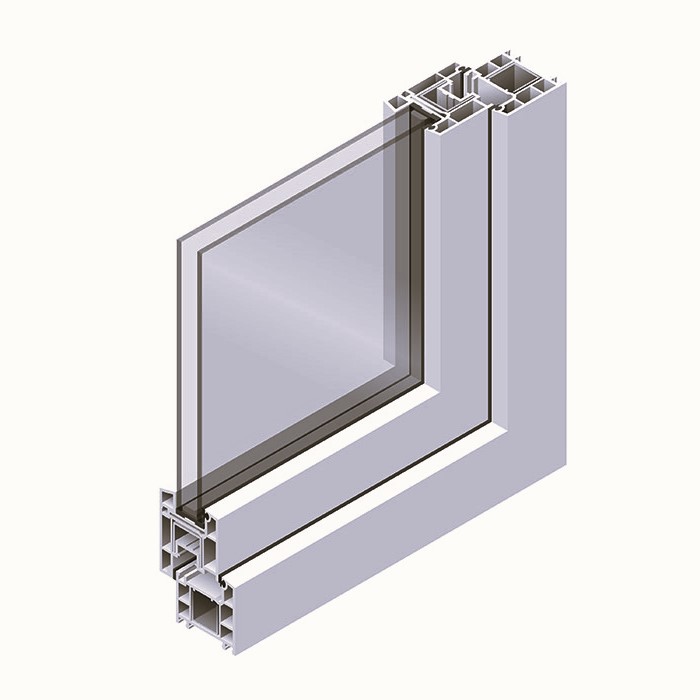

- Multiple Glazing: Double and triple glazing systems consist of multiple layers of glass separated by air or gas-filled spaces. These layers provide additional insulation, reducing heat transfer and enhancing energy efficiency.

- Insulating Gas Fillings: Inert gases, such as argon or krypton, can be injected between the layers of glass to further enhance the insulating properties. These gases have low thermal conductivity, minimizing heat transfer and improving energy efficiency.

- Smart Glass: Smart glass, also known as switchable glass, can dynamically change its properties in response to external factors, such as sunlight intensity or electric current. This glass technology can control solar heat gain, glare, and privacy, contributing to energy savings and occupant comfort.

To learn more about energy-saving glass production and standards, you can visit the following sources:

- Energy Efficiency Standards and Regulations – Canada.ca

Standards and Regulations for Energy-Efficient Glass

Standardization bodies play a crucial role in ensuring the quality and performance of energy-saving glass. Several international standards and regulations govern the manufacturing, testing, and labeling of energy-efficient glass products. These standards include:

- ISO 9050: This standard specifies the properties and performance requirements of solar control glass, including visible light transmission, solar energy transmittance, and thermal insulation.

- EN 1279: European Norm (EN) 1279 sets the standards for the insulating glass units, including requirements for gas fillings, edge sealing, and durability testing.

- ENERGY STAR: ENERGY STAR is a voluntary program administered by the U.S. Environmental Protection Agency (EPA). It sets energy performance criteria for windows, doors, and skylights, certifying products that meet specific energy efficiency requirements.

Conclusion

The production of energy-saving glass has witnessed significant advancements, driven by the need for energy-efficient buildings. Energy-saving glass offers multiple benefits, including reduced heat transfer, improved insulation, and enhanced occupant comfort. Innovations in manufacturing techniques, such as low-E coatings, multiple glazing, and smart glass, have contributed to the improved energy performance of glass. Standardization bodies, including ISO and ENERGY STAR, ensure that energy-efficient glass products meet specific quality and performance criteria. By embracing these innovations and adhering to established standards, the construction industry can create buildings that are environmentally sustainable, energy-efficient, and comfortable for occupants.