Glass is a versatile material used in a wide range of applications, from architectural structures to household items. While glass offers transparency and aesthetic appeal, it can be fragile and prone to breakage. To enhance its safety and strength, glass tempering techniques are employed. These techniques involve controlled heating and rapid cooling processes that transform ordinary glass into tempered glass, making it more resistant to thermal stress and mechanical impact. In this article, we will explore the importance of glass tempering techniques in ensuring safety and strength.

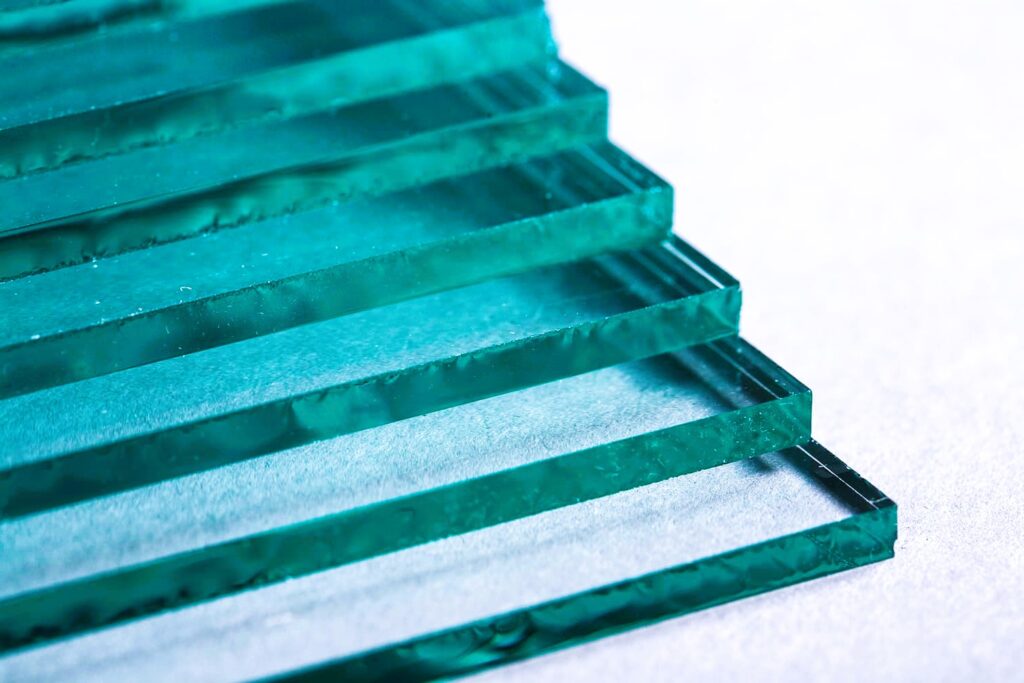

Tempered glass is produced by subjecting float glass, which is the standard flat glass, to a tempering process. The process involves heating the glass to a high temperature of around 600 to 700 degrees Celsius and then rapidly cooling it using jets of cold air. This rapid cooling creates a state of high compression on the surface of the glass, while the interior remains in tension.

One of the primary benefits of tempered glass is its increased strength and durability. The compressive stress on the surface of the glass strengthens it, making it resistant to external forces. Tempered glass is known to be four to five times stronger than ordinary glass of the same thickness. This enhanced strength reduces the risk of breakage and makes tempered glass a preferred choice for applications where safety is crucial, such as in windows, doors, shower enclosures, and automobile windows.

Another significant advantage of tempered glass is its safety features. When tempered glass does break, it shatters into small, pebble-like pieces with rounded edges, known as “dice.” These small pieces reduce the risk of serious injuries compared to the sharp, jagged shards that result from the breakage of ordinary glass. This is particularly important in areas where human contact is likely, such as in doors or glass partitions. The safety aspect of tempered glass is why it is often required by building codes and regulations for certain applications.

Additionally, tempered glass exhibits excellent resistance to thermal stress. It can withstand rapid temperature changes without cracking or breaking. This property is essential in environments where temperature fluctuations are common, such as in glass panels exposed to sunlight or in kitchen appliances. Energy-Efficient Windows in Ontario: Benefits and Technologies.

For more information on glass tempering techniques and industry standards, please visit the following sources:

- Wikipedia: Tempered Glass

To ensure the quality and safety of tempered glass, industry standards and regulations play a vital role. Organizations such as the American National Standards Institute (ANSI) and the Canadian Standards Association (CSA) have established guidelines and certification programs for tempered glass. These standards outline the requirements for the tempering process, including the heating and cooling cycles, the stress levels to be achieved, and the quality control procedures. Compliance with these standards guarantees that tempered glass meets rigorous safety and strength requirements.

In conclusion, glass tempering techniques are instrumental in enhancing the safety and strength of glass. By subjecting float glass to controlled heating and rapid cooling processes, tempered glass is created, which offers increased strength, durability, and safety features. The ability of tempered glass to resist breakage, shatter into harmless pieces, and withstand thermal stress makes it a preferred choice in various applications. Adherence to industry standards ensures that tempered glass meets strict quality and safety criteria, providing peace of mind for manufacturers, builders, and end-users.